how do rivets work diagram

Pop rivets consist of two parts. Rivets with this kind of heads are used most of all.

The Selvedge Denim Leather Apron Leather Apron Aprons Patterns Aprons For Men

When calculating the suitable length of a Peeled rivet take the total thickness of materials to be fastened and add on double the rivets diameter.

. A spring then makes the piston return to its first position. When two plates are to be fastened together by a rivet the holes in the plates are punched and reamed or drilled. Punching is the cheapest method and is used for relatively thin plates and in structural work.

Minimum Diameter of Rivet Shank D 3 x Thickness of the Thickest Sheet That is Being Joined A15 D For rivets of diameters of the rivet shank up to 20 mm Length of Rivet Shank L S Allowance A A general rule is that the rivet should have a diameter of at least three times the thickness of the thickest sheet that is being joined. The material of rivet should be tough and ductile. Before being installed a rivet consists of a smooth cylindrical shaft with a head on one end.

Use the right tool. The rivet is deformed by pounding or smashing of the tail which makes the material flatter and usually causes the tail to be expanded by about one and a half times the size of the stems original diameter. In short to tell about how does a pneumatic rivet gun work- compressed air pushes the rivet into its place when one presses the trigger.

Diagram of how an orbital riveting works Orbital riveting edit Orbital riveting machines have a spinning forming tool known as a peen which is gradually lowered into the rivet which spreads the material of the rivet into a desired shape depending upon the design of the tool. This Design Squad Nation animation shows how a pop rivet clamps two pieces of material together. Follow up with a punch and a hammer.

The rivets are kind of the adjacent surfaces between the two parts to be joined. When installed the rivet is either drilled placed or punched into a hole afterwards the tail is then deformed holding the rivet in place. Drill out the center of the rivet carefully.

Riveting is a forging process that may be used to join parts together by way of a metal part called a rivet. A rivet is divided into 3 parts ie the head at one end the tapered tail and shank the portion between the head and tail as shown in the figure. This type of rivets is shown in the figure.

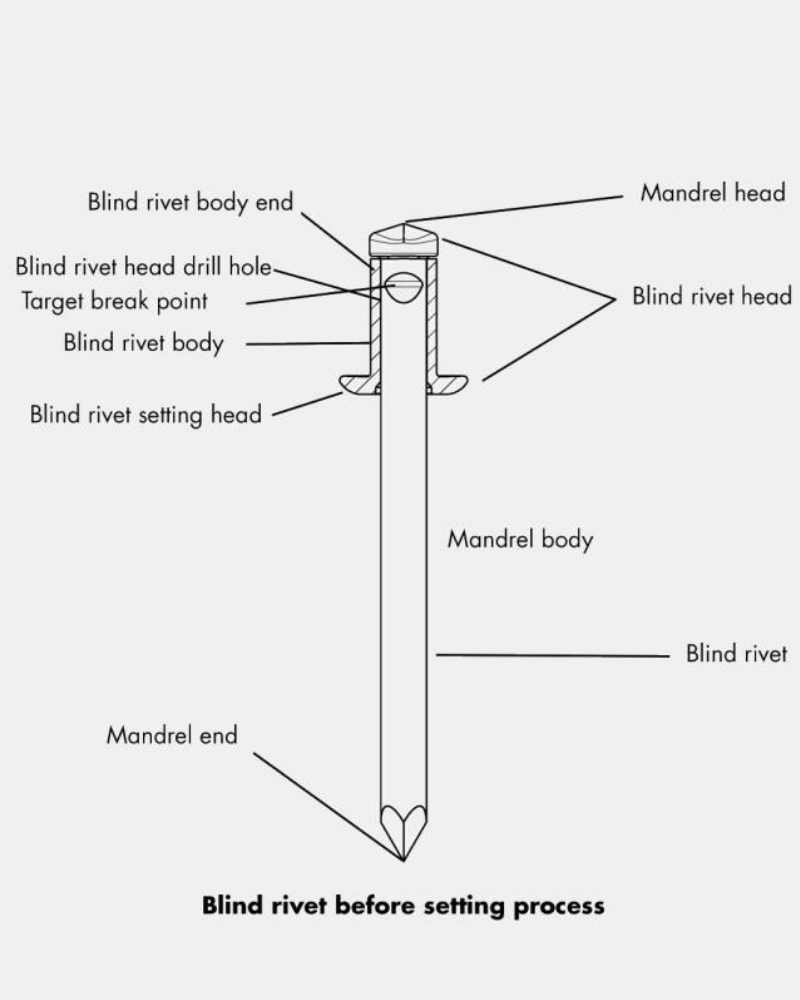

Blind rivets are a two-part fastener consisting of a shell and a headed stem mandrel assembled so the shell can be placed into the work to be fastened. Then the buck distorts the tail of the rivet. After the desired clamping force is achieved.

That is why it is widely used in bridges made of iron material. Notice how in the diagram to the right the portion of the. The way that a blind rivet works is that the thick head is driven into the hole being fastened while a rivet gun pulls on the thin mandrel.

A rivet is a permanent mechanical fastener consisting of a head at one end and a cylindrical stem at the other end called the tail which has the appearance of a metal pin. A rivet is a permanent mechanical fastener. The two pieces of plastic or aluminium are drilled to a size slightly larger than the rivet.

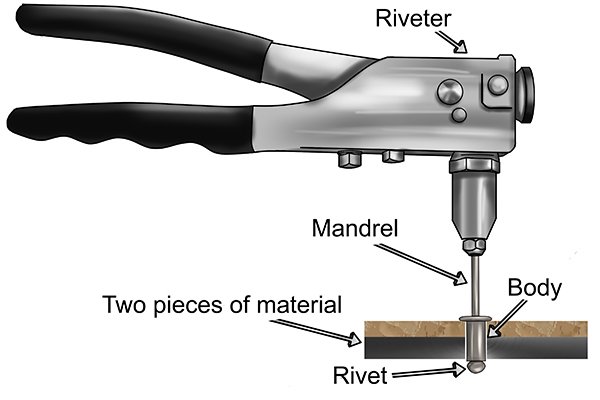

The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together. Rivets are used to join large structural members small electronic assemblies and just about any manner of part falling between these extremes. 10mm 96mm 196mm.

Remember from the diagram above the rivet is to act like a clamp we do not need or want to expand the body size of the rivet at all. A rivet body is the portion of the rivet that deforms and stays in the installation. Blind Rivet diameter 48mm x 2 96mm.

The rivet is set by drawing the stem through the shell which causes the shell to deform and clamp the material securely. Then both ends are formed over the connection joining the parts securely. A straight metal piece will be inserted via the hole or cavity provided for.

Because rivet nuts are made to be automated and used in factory settings power installation tools are often mounted to a six-axis robot. The pop rivet is passed through both holes in the sheet plastic aluminium. Since punching injures the material around the hole therefore drilling is used in most pressure-vessel work.

The joints of this rivet are very strong. Move rivet tool down against flange of rivet so that nosepiece is again. Rivets come in 132 length increments.

If you do a lot of work on machines you are going to wind up having a variety of rivet lengths on hand to pick from. Material thickness 10mm. Choose a rivet length of 1821mm.

2 What is rivet riveting process definition meaning Image. The metal work piece used to form the. This creates a compressive force between the head and the material being fastened deforming the head and creating a permanent fastener.

Among the primary benefits of rivet nuts are that they offer a faster assembly and lower installation costs compared to other fasteners. As it is a permanent joint it cannot be disassembled without the failure of the machine component. You just need to place the rivet on the end of the tool insert into the hole and then fire.

Select a drill bit that is smaller than the hole which your rivet is positioned in. This is commonly referred to as an interlock rivet. Snap head or cup head rivets.

Structural rivets work slightly different from the typical blind rivet. The end opposite to the head is called the tail. A pop rivet is then inserted through the drilled hole and the rivet body is brought into contact.

Its diameter is 16D and its height is 07D. The first part is called the rivet body also known as the shell or hat and the second part is called the mandrel also known as the stem. Thou shalt use the correct length rivet for the job.

When finished the tail has the appearance of. Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. A straight metal piece is connected through the parts.

Snap head or cup head rivets. The head is of a semi-circle in shape. This Design Squad Nation animation shows how a pop rivet clamps two pieces of material together.

On installation the rivet is placed in a punched or drilled hole and the tail is upset or bucked so that it expands to about 15 times the original shaft diameter holding the rivet in place. This will ensure that it doesnt remove any unnecessary material from your work pieces. In situations where access to both sides of a component is limited a hole is first drilled through the parts to be joined.

The rivet pliers are pushed on to the pin of the rivet and the handles are pulled together. A structural blind rivet has a built-in internal locking mechanism that is designed to hold the mandrel inside of the rivet after the exposed portion snaps. The rivet acts to join the parts through adjacent surfaces.

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

How Rivets Work Rivets Fasteners Screwdriver

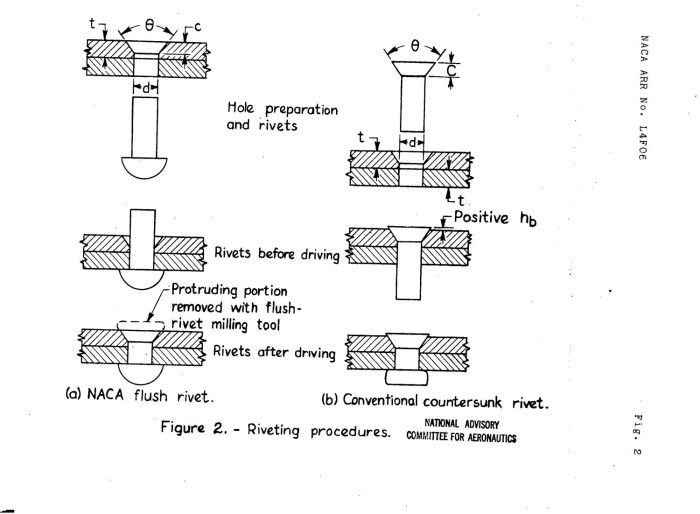

Naca And Conventional Riveting 2 Download Scientific Diagram

What Is A Blind Pop Rivet Gesipa

Usually Rivets From 3 16 Diameter Through 1 2 Are Easy To Obtain In Commonly Useful Lengths Custom Rivets Fo Blacksmithing Sheet Metal Tools Forging Tools

Blind Fastener Properties Blinds Installation Bulb

Rivets Plan Download Free Vintage Model Aircraft Plan Model Airplanes How To Plan Model Planes

Riveted Joints Definition Applications Operations Types Studentlesson

How Does A Blind Rivet Work Wonkee Donkee Tools

Free Body Diagram Of A Rivet Showing The Influence Zone Download Scientific Diagram

Illustration Of The Friction Stir Blind Riveting Process A The Download Scientific Diagram

Schematic Diagram Of Friction Self Piercing Riveting Process A Rivet Download Scientific Diagram

What Is Rivet Definition Types Working Process Engineering Choice

What Is A Rivet How Is Riveting Done Riveting Definition Types Of Rivet

4 Tips For Stronger Blind Rivet Joints Machine Design Machine Design Blinds Joint